Product packaging serves two primary functions: it protects the products inside, and it attracts buyers with its visual appeal. While putting an item in a package seems simple enough, it’s actually a major part of product development and sales, requiring artistic skills and innovative technologies. Companies strive to create the most creative, attractive packaging to set themselves apart from the competition while protecting their goods in a cost-efficient way.

Blister packaging and skin packaging are two types of packaging options, each of which offer their own unique features suitable for packaging different products.

Blister Packaging

Blister Packaging

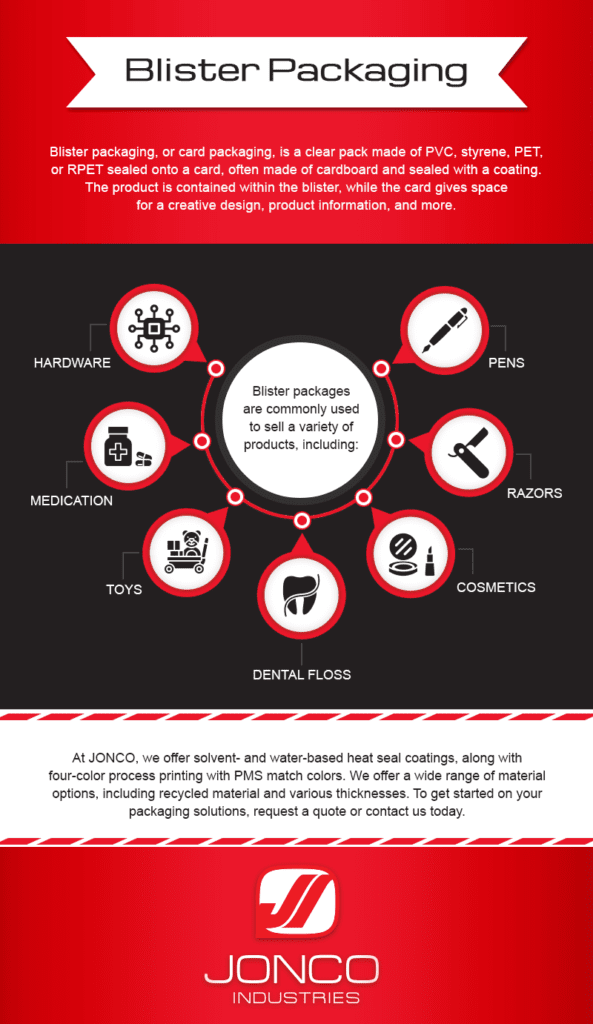

Blister packaging, or card packaging, is a clear pack made of PVC, styrene, PET, or RPET sealed onto a card, often made of cardboard and sealed with a coating. The product is contained within the blister, while the card gives space for a creative design, product information, and more.

Blister packages are commonly used to sell a variety of products, including:

- Pens

- Razors

- Cosmetics

- Dental Floss

- Toys

- Medication

- Hardware

Blister packs are especially cost-effective when used for combination production runs, as the costs of set-up and tooling are shared among several cards printed on the same sheet. It can also be used for dedicated runs.

At JONCO, we offer solvent- and water-based heat seal coatings, along with four-color process printing with PMS match colors. We offer a wide range of material options, including recycled material and various thicknesses.

Skin Packaging

Skin packaging is achieved via heat sealing, a versatile technique that can be used on a wide range of materials using an automated process. The product is typically placed against paperboard or corrugated cardboard before the film is applied and heated to create an airtight seal against the product. You can choose your backing material and thickness according to the size and weight of your product, while the film is typically a polymer like polyethylene or PVC.

This style of packaging is both efficient and attractive, as the film is molded to the contours of the product and the card allows for the display of multiple components. Companies like skin packaging for its versatility, simplicity, and clear view of the product inside. You’ll notice it in a variety of settings, including:

- Retail

- Military

- Automotive

Consumers appreciate being able to see the products before they buy them. Clear film is theft resistant, offering product protection against potential damage during handling and transit since the tight seal prevents the product from jostling or shifting. These packages can be created with a hang hole for easy display and offer a low cost-per-unit for high volume runs.

JONCO Industries for Your Packaging Needs

As a trusted supplier of die-cuts, protective packaging, dry and liquid packaging, and more, JONCO is proud to offer custom packaging and labeling solutions. From prototypes to full-scale production, we have decades of experience designing and manufacturing high-quality, attractive packaging for a wide range of products. Our experienced team of engineers, designers, and craftsmen will work with your design specifications to bring your ideas to life. To get started on your packaging solutions, request a quote or contact us today.