As a leading, full-service manufacturing and fulfillment house, JONCO Industries, Inc. offers a comprehensive list of end-to-end services including laser cutting and routing, additive manufacturing, water jet cutting, industrial sewing, fabrication, and packaging, and printing services. Our client, Stone Creek Coffee out of Milwaukee, recently learned the value of JONCO’s capabilities as a one-stop shop for solutions in design, manufacturing, engineering, and even production.

Stone Creek Coffee is a craft coffee producer founded in Milwaukee in 1993. SCC originally came to JONCO to fabricate a steel sign using our water jet cutter. Upon touring our primary facility, the company’s director of partnerships thought there could be another opportunity for JONCO to help represent the SCC brand on a bigger scale than they were capable of handling in-house.

The Problem: Scaling Up

Stone Creek Coffee needed larger production and product development – from concept to production – for a kiosk project designed for brand engagement in out-of-store retail locations. JONCO’s experienced staff quickly went to work to brew up a solution for Stone Creek Coffee.

Specifically, SCC required the production of 100 eleven-piece units for retail kiosk locations within a four-to-six week window. Additionally, the design had to adhere to SCC’s brand standards, as well as, their design and execution expectations.

The JONCO Solution

The initial steps to this project involved defining and organizing the full project scope. The initial meeting included establishing deadlines, distinguishing deliverables, and determining accurate and competitive pricing.

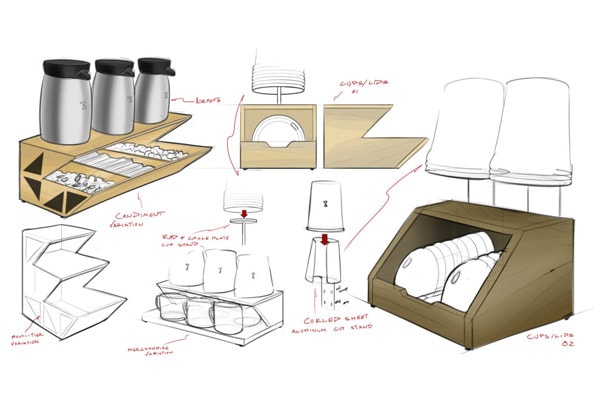

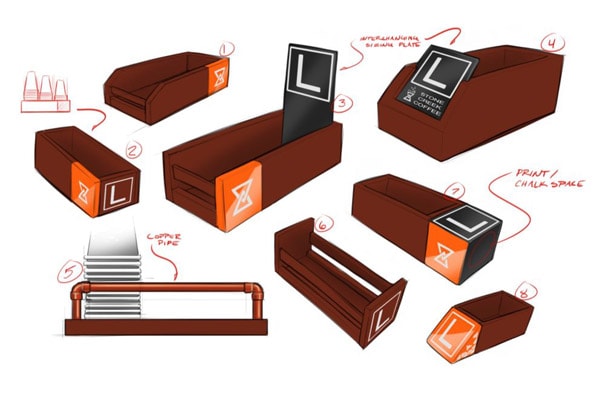

After touring the SCC facility, JONCO’s creative team went to work designing the ideal product. Moving through the various stages of design, our staff provided concept selection, digital prototyping, and a physical scale prototype to help visualize the full-scale end product.

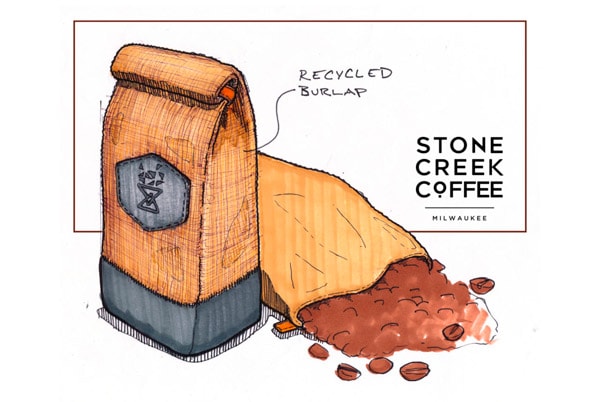

Ultimately, the Stone Creek Coffee project required a broad range of materials, including hardwood and lumber, steel, acrylic, paint and stain, and various small items such as assembly hardware, PVC, burlap, and coffee. Several prototypes were produced throughout the process to ensure the project continued to meet SCC’s expectations. Our designers provided drawings and renderings, SolidWorks visualizations, material prototypes, and a full-scale prototype to verify all the specifications were continuously on target.

Our Results

JONCO’s experienced staff and cutting-edge production facility were able to relieve our client of the production pressure associated with a fabrication project of this magnitude. Additionally, by providing an extra design team to assist the Stone Creek Coffee team, we were able to match new designs to their existing branding.

The designers and engineers at JONCO delivered a superior solution by using a broad range of our in-house fabrication services, such as laser cutting, waterjet cutting, CNC routing, design, fabrication, and assembly services. By choosing to work with JONCO, Stone Creek Coffee received an experienced design staff, transparent processes and pricing, functional prototypes, and high-quality products and services.

Commitment to customer service and quality control allow JONCO to meet the requirements for nearly any customer production, assembly, warehousing, shipping, and/or fulfillment project.

To learn more about how JONCO Industries Inc. can help your company meet your special production or fabrication needs, contact us today for a quote or to schedule a consultation. The professionals at JONCO are looking forward to helping you solve your most complex problems.