JONCO Industries, Inc. is a full-service manufacturing and fulfillment house with extensive experience in product development and engineering. Specializing in design, production, finishing, and everything in-between, our team offers custom printing, cutting, sewing, and packaging services as well as 3D work. Committed to realizing even the most complex projects, we work to build and maintain close relationships with all of our customers and provide them with the resources they need to take business to the next level.

Problem: Make Manufacturing Work for You

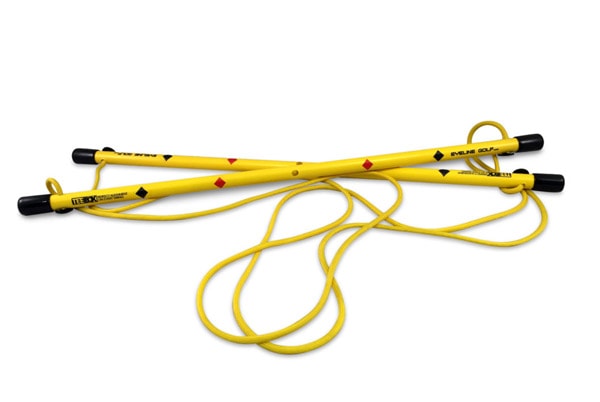

Eyeline Golf creates specialty training aids to help golfers master their craft and improve their personal bests. Putting aids, swing aids, and target circles are just a few examples of Eyeline’s innovative tools for improvement. To date, the Colorado company has sold its products to thousands of golfing enthusiasts across the country, including some 570 players on the PGA Tour.

In addition to golf, CEO Sam Froggatte has another lifelong passion: sales. Starting his career with IBM in 1974, Sam later became an independent sales consultant for 15 years. In 2002, he combined his skills with his lifelong passion for sports by founding Eyeline Golf.

The JONCO Solution

Sam and his team had the ideas, the sales skills, and the energy to succeed — but not the manufacturing. In fact, Eyeline’s original product designs came out of Sam’s garage. The company quickly realized that it needed to outsource manufacturing before it could scale operations.

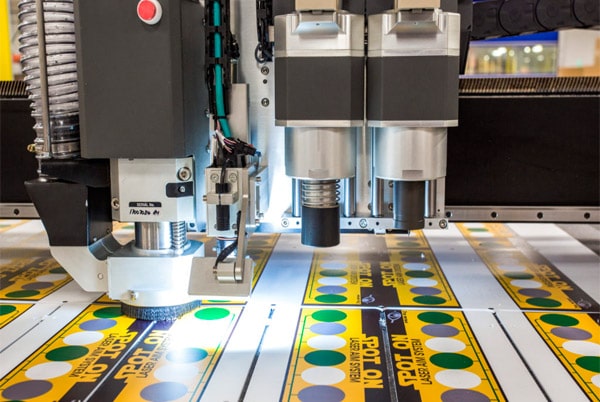

Eyeline soon approached JONCO for manufacturing help. We started from the ground up, running detailed analysis to streamline production and reduce operating costs. That initial meeting proved to be the foundation for a longstanding partnership. Today, we work with Eyeline routinely: we design products with their specifications to simplify manufacturing and produce their products at the most effective price points.

Every other month, JONCO’s creative team touch base with Eyeline for product design collaboration, resulting in a constant flow of production and manufacturing work totaling thousands of units a month. Their team sends us early product prototypes, and we go over the full design for testing and feedback. JONCO designers provide the key tweaks for manufacturing and material selections to satisfy every player. Our engineers then craft efficient production plans to avoid issues and cut costs, guaranteeing a superior result in the process.

A One-Stop Shop

With the help of JONCO, Eyeline’s products have become necessities for golfers at every level. Today, they’re revered by recreational players and professionals alike.

Over the years, JONCO has become essential to Eyeline’s operations. Our team provides comprehensive feedback on its designs and collaborates with it on every aspect of the manufacturing process. As the company continues to expand, we still work closely with its designer and production manager on current and new products, using our expertise to help them produce the finest golfing aids on the market.

JONCO creates professional, high-quality designs supported by expert manufacturing. From design and prototyping to final packaging, we’re here to solve even the most difficult problems. To learn more about our specialty work or schedule a consultation for your next project, reach out to the team today!