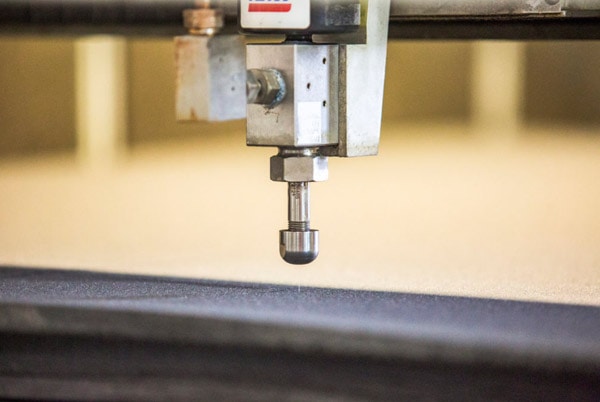

We have two types of waterjet cutting at our facility, pure waterjet (cuts up to 4 inches thick) and flow abrasive waterjet (cuts up to 8 inches thick).

Our pure waterjet cutter generally cuts foams, leather and rubber type material with a table processing area of 58 x 68 inches. The flow abrasive cutter can cut all heavy duty material like metal (all kinds), glass, granite, etc. with sizes up to 6 x 12 feet.

Our Flow abrasive waterjet cutting machine uses a high-velocity stream of water mixed with abrasive particles to cut a variety of materials for the fabrication and manufacturing of parts.

- Cuts all materials from rubber and plastics, aluminum and hardened steels, to glass and granite.

- Cuts parts up to 6 x 12 feet in dimension and 8 inches thick.

- Our waterjet cutter has an upgraded pressure output of 94,000 PSI.

- Down to .003 inch output tolerance upon request.

| Cutting Specifications | |

|---|---|

| Machine Type | 1 Pure and 1 Abrasive Waterjet Machine |

| Cutting Axis | 3-Axis |

| Machine Type | CNC Machine |

| Abrasive Waterjet Cutting Material | Alloys, Aluminum, Brass, Bronze, Copper, Ferrous & Non-Ferrous Metals, Stainless Steel, Carbon Steel, Steel, Titanium, Glass, Wood, Granite |

| Waterjet Cutting Material | Foams, Rubbers, Flexible Packaging Materials, Neoprene, Gasket Materials, Vinyl, Plastic, ABS, Acrylic, Corrugated Cardboard, Polyethylene, Polypropylene, Polyurethane |

| Cutting Thickness with Abrasive Cutting | Up to 8 in |

| Waterjet Cutting Length | 0 to 118 in |

| Abrasive Waterjet Cutting Length | 0 to 12 ft |

| Waterjet Cutting Width | 0 to 60 in |

| Abrasive Waterjet Cutting Width | 0 to 6 ft |

| Waterjet Pressure (Abrasive Cutter) | Has 94,000 PSI Intensifier Pump, Cuts Faster and Thicker Materials |

| Tolerance (+/-) | Down to 0.003 in |

Additional Services From Jonco

Below are some of the additional complementary services we offer to enhance your project.

Warehousing & Fulfillment

The Jonco team offers the most efficient and cost-effective delivery service. We can then ship to you or directly to your customer. Our warehousing and fulfillment services are safe, secure, and inexpensive.

Complete Finishing Services

Whether you require cutting, sewing, or packaging, every step required for your project is offered in-house. This allows us to easily handle high-volume orders while ensuring quick turnarounds and superior quality — even when working on complex, specialty, or brand-new products.

Working With The Jonco Team

With a dedicated team of experts and a fleet of high-performance equipment, we’re ready to make your ideas a reality. To learn more about our top-of-the-line waterjet cutting capabilities, contact us today.