When Jonco worked on a special sewing request 30 years ago, we never looked back. Custom fabric cutting and specialty sewing join a variety of start-to-finish services in our production portfolio, allowing us to create top-of-the-line apparel, bags, tool covers, uniforms, purses, backpacks, and much more.

Our industrial contract sewing services can accommodate projects large and small, from independent short runs to large commercial contracts.

Automated Fabric Cutting Capabilities

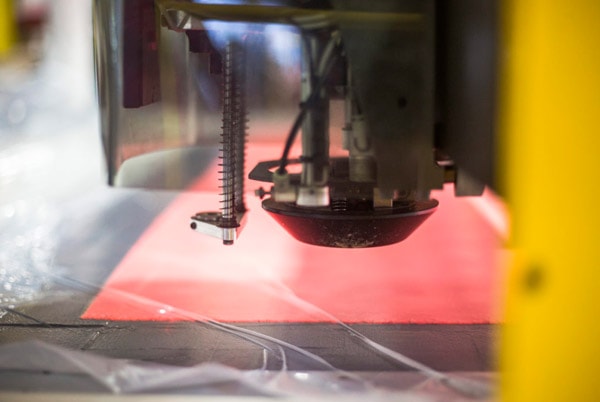

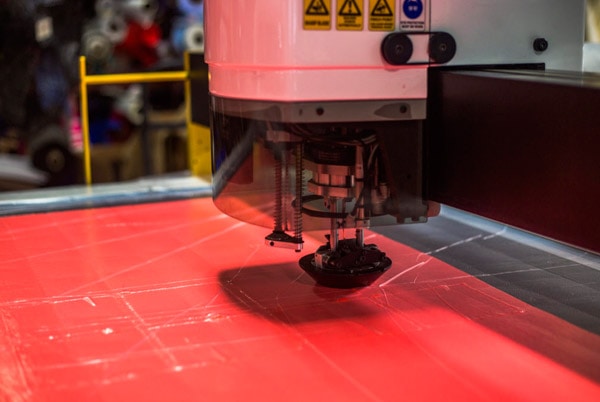

We’re proud to offer a full range of sewing and embroidery capabilities, including automated custom fabric cutting. Our digital fabric cutter, the Pathfinder K5000 Apparel Cutting System, can manage rolls of fabric as large as 61 inches. Outdoor shade structures, furniture patterns, marine and automotive fabric patterns, and even military-grade projects can all be custom cut with this sophisticated system.

Backed by a full fleet of specialty equipment and skilled craftspeople, we support large-scale digital fabric cutting with finishing, and sewing services to bring any project to life.

We routinely work with a wide range of materials, including:

- Nylon

- Cotton

- Leather

- Canvas and Waxed Canvas

- Rubber

- Polyester and Synthetic Blends

- Felt

- Laces

- Belts

- Straps

- Metal and Plastic Hardware (Zippers, Grommets, D/O/Triangle Rings, Buttons, and Clips)

Cutting is fast, efficient, and extremely accurate, allowing us to offer reliable, long-lasting low-ply or multi-ply fabric solutions.

The Fabric Cutting Process

Our fabric cutting capabilities are just one aspect of Jonco’s custom sewing services. Banners, clothing, bedding, bags, flags, covers, furniture — the JONCO team does it all. We manage your project from start to finish, beginning with your custom design.

- We receive your initial design and create a physical pattern or prototype. Once we fine-tune the pattern, it can be reproduced with great accuracy.

- Our engineers digitize the cut pattern and optimize it for the Pathfinder cutter.

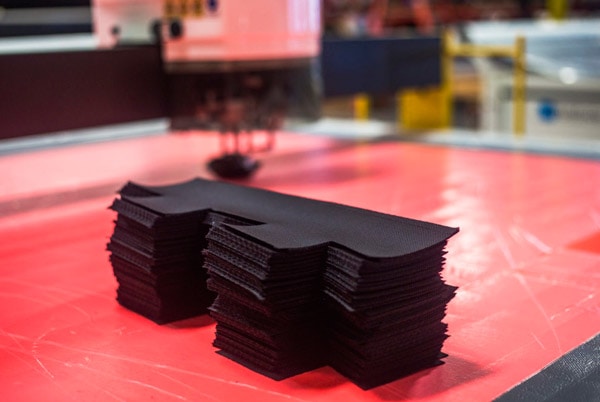

- We can readily cut both small batches (in the hundreds of products) and production-scale runs (of 1,500 items or more).

- After the run has been completed, our team will follow up with any additional finishing services needed, all at our home facility.

- We coordinate final shipping and pickup to ensure quick, efficient delivery.

If you don’t see a project like yours listed here, reach out today and we’ll find a solution.

Additional Services From Jonco

We work to accommodate the special needs of any industry, including startups, tool manufacturers, the military sector, and textile/apparel manufacturers.

Our sewing department is supported by a full range of complementary services, a couple of which are listed below.

In-House Design

We believe in creating work that is innovative, well-designed, and practical, not to mention economical to produce. Our talented team offers start-to-finish services, including prepress work and design development, custom color matching and printing, material guidance, and graphic design. We can work with many different fabrics and flexible materials.

Dye Sublimation Printing

We manage jobs of all sizes with a wide range of available substrates, inks, and print formats. Jonco’s dye sublimation printing joins digital printing, roll-to-roll printing, large flatbed UV printing, and even 3D printing to help our team accommodate your every need.

Working With the Jonco Team

Whether working with small businesses or large corporate clients, we can create a huge range of custom-cut fabrics — from automotive fabrics to high-performance uniforms. Our sewing department is prepared to handle your project from the design stage all the way to full-scale production.

To learn more about our fabric cutting technology and custom sewing services, or to request a quote for your specific needs, reach out to the team today.